Your Guide to Selecting the Right Ball Valves

Are you tired of dealing with leaky pipes or inefficient fluid control systems? When these issues happen, there can be a lot of pressure to find the perfect solution. That’s where Hyspeco’s guide to selecting the right ball valves can help. Having precise control of your hydraulic system starts with the right ball valve. Below, you’ll learn the intricacies involved in making the right choice, including types of ball valves, key features to consider, how to choose the right size, and more.

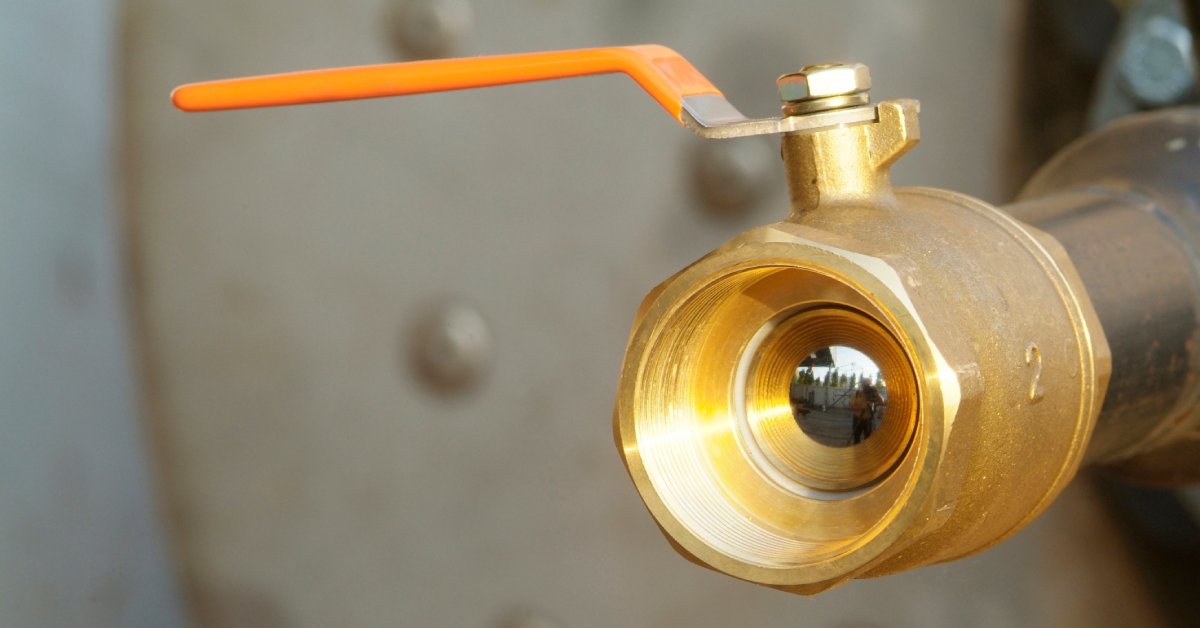

What Is the Purpose of a Ball Valve?

Ball valves control the flow of liquids and gases. The ball has a hole in the middle of it and can rotate within the valve by means of a lever that users can turn on the outside. When the flow inlet and hole align, fluid can pass through, which means the valve is open. Conversely, when the ball is rotated to block the hole, the valve closes, effectively stopping the flow.

Understanding the Common Types of Ball Valves

Each type of ball valve has unique features and advantages. Each design addresses specific needs based on application requirements, like pressure tolerances, flow control, and efficiency. Understanding these types will help you select the most suitable ball valve for your hydraulic systems.

Floating Ball Valves

A floating ball valve has a ball that is held in place by two valve seats. When the system applies pressure, the ball is pushed against the downstream seat, creating a tight seal. These valves are most suitable for lower-pressure applications.

Trunnion-Mounted Ball Valves

In a trunnion-mounted ball valve, trunnion bearings support the ball, alleviating some stress on valve seats. This design is ideal for high-pressure applications and ensures stable operation, as the fixed ball mitigates leakage.

V-Port Ball Valves

This type of valve features a V-shaped seat and a ball with a similarly shaped hole. This valve allows for excellent flow regulation. When your system requires precise flow control, such as in metering applications, V-port ball valves might offer the precision you’re after.

Full-Port Ball Valves

A full-port valve (also known as a full-bore valve) has an oversized ball that allows fluid to pass through without any restriction. This design minimizes pressure drop across the valve and is often the best when system efficiency is the main priority.

Reduced-Port Ball Valves

Unlike full-port valves, reduced-port valves (also known as reduced-bore valves) have a smaller ball, which results in a reduced flow. These valves are typically used when flow restriction is not a concern, and a cost-effective solution is the preference.

Materials and Construction of Ball Valves

The material and construction of a ball valve play a significant role in its performance and durability. Common materials include brass, stainless steel, and PVC. Each has its strengths and limitations, depending on the application.

For one, brass ball valves are popular for their resistance to corrosion and affordability. They are common in residential and commercial plumbing. Stainless steel ball valves, on the other hand, offer superior strength and chemical resistance, making them ideal for industrial applications where high pressure and temperature are factors.

Finally, PVC ball valves are lightweight and resistant to a wide range of chemicals, making them suitable for water and chemical handling applications. When considering material, it’s important to assess the specific environmental conditions and chemical exposure the valve will face.

Key Features To Consider When Choosing Ball Valves

It is essential to consider the following features to ensure that your selected ball valve will efficiently and reliably serve its intended purpose within your system:

- Pressure rating: The valve should be able to withstand the maximum operating pressure that your system may experience.

- Temperature rating: Consider the temperature range in which the valve will operate. The valve’s materials must be able to endure these conditions without degrading.

- Material compatibility: Match the valve material to the substances it will encounter to prevent corrosion and chemical reactions that could impair function.

- Actuation method: Determine if manual operation is sufficient or if you need an automated actuator for remote or precise control.

- End connection type: Choose connection types that are compatible with your existing piping system (i.e., threaded, welded, flanged, etc.).

How To Choose the Right Size for Ball Valves

To choose the right ball-valve size, first measure the diameter of the pipeline in which you will integrate the valve. Ensure the valve size matches the pipe size to maintain system efficiency and avoid pressure drops.

Additionally, account for the flow rate requirements and consult the valve’s flow coefficient (Cv) data, which indicates how much flow can pass through the valve. Selecting the correct valve size will guarantee optimal performance without restricting or unnecessarily expanding the system flow.

Avoiding Common Mistakes in Ball Valve Selection and Use

By being aware of these common mistakes and avoiding them, you can enhance the reliability and performance of your ball valve systems.

Ignoring System Requirements

One common mistake is neglecting to assess the specific requirements of your system before selecting a ball valve. Failing to account for flow dynamics, pressure conditions, and environmental factors can lead to the selection of an inappropriate valve type, resulting in inefficiencies or system failure.

Overlooking Maintenance Needs

Many users underestimate the importance of regular maintenance. Ball valves require routine inspection and cleaning to promote proper functioning over time. Neglecting maintenance can lead to wear and tear, reduced performance, and possible leakage.

Misjudging Environmental Considerations

Selecting a valve without considering the environmental conditions it will be exposed to can lead to premature corrosion or degradation. Ensure that the material and design of the ball valve can withstand any relevant humidity, temperature variations, and exposure to corrosive substances.

Improper Installation

Incorrect installation can cause significant operational issues. Install ball valves in accordance with manufacturer instructions, with attention to proper alignment, connection type, and torque specifications. This will prevent leaks and ensure optimal function.

Selecting the right ball valve is key to ensuring your fluid control systems are effective and reliable. Hyspeco’s guide is an invaluable resource, helping you understand various ball valve types, materials, sizing, and features to make informed decisions.

Hyspeco also offers a wide range of Parker ball valves and other high-quality components for efficient hydraulic systems. By selecting the right products from us and understanding their uses, you can protect your operations from inefficiencies and failures.