4 Types of Hydraulic Motors and Their Applications

Hydraulic motors are robust machines at the heart of various industrial applications, converting hydraulic energy into mechanical energy with remarkable efficiency. Their versatility and reliability make them indispensable in sectors ranging from construction and agriculture to manufacturing and beyond. Discover the different types of hydraulic motors and their applications, gaining insights into their unique features and optimal uses.

Gear Motors

Gear motors are among the most commonly used hydraulic motors, known for their simplicity and durability. They consist of two gears that mesh together inside a housing.

When hydraulic fluid enters the motor, it causes the gears to rotate, converting hydraulic pressure into mechanical rotation. This straightforward mechanism makes gear motors a go-to choice for many applications that require a robust and cost-effective solution.

Key Characteristics

One of the defining characteristics of gear motors is their ability to operate under high-pressure conditions while maintaining exceptional efficiency. They are built to withstand tough environments and are less susceptible to damage from contaminants in the hydraulic fluid, thanks to their rugged construction. Additionally, gear motors are relatively easy to maintain and repair, which further enhances their appeal in industries where downtime can be costly.

Industry Applications

Gear motors find application in a variety of sectors, including agriculture, construction, and material handling. In agricultural equipment, they power implements like seeders and harvesters, ensuring reliable performance even in challenging field conditions.

Gear motors are employed in construction machinery for concrete mixers and compactors, where their reliability and durability are essential. Furthermore, they are used in conveyor systems and other material-handling equipment that demand consistent power delivery.

Vane Motors

Vane motors, also known as rotary vane motors, function through a series of vanes mounted on a rotor. These vanes slide in and out of the rotor slots, creating chambers that expand and contract as hydraulic fluid flows through the motor. This action results in the rotation of the motor's output shaft, effectively converting hydraulic energy into mechanical motion.

Key Characteristics

Vane motors are prized for their smooth operation and precise control. They offer excellent torque characteristics at low speeds, making them ideal for applications that require meticulous movement. Additionally, vane motors provide a good balance between cost and performance, offering a reliable option for applications where precision and efficiency are paramount.

Industry Applications

Vane motors are widely used in industrial automation, where their precision and smooth operation are crucial. They are employed in robotics, where precise movement and control are required for tasks such as assembly and packaging.

Vane motors also find application in machine tools, where they ensure accurate positioning and smooth operation of cutting and shaping equipment. Furthermore, these motors are used in injection molding machines, where their ability to provide consistent torque at low speeds is essential for producing high-quality plastic components.

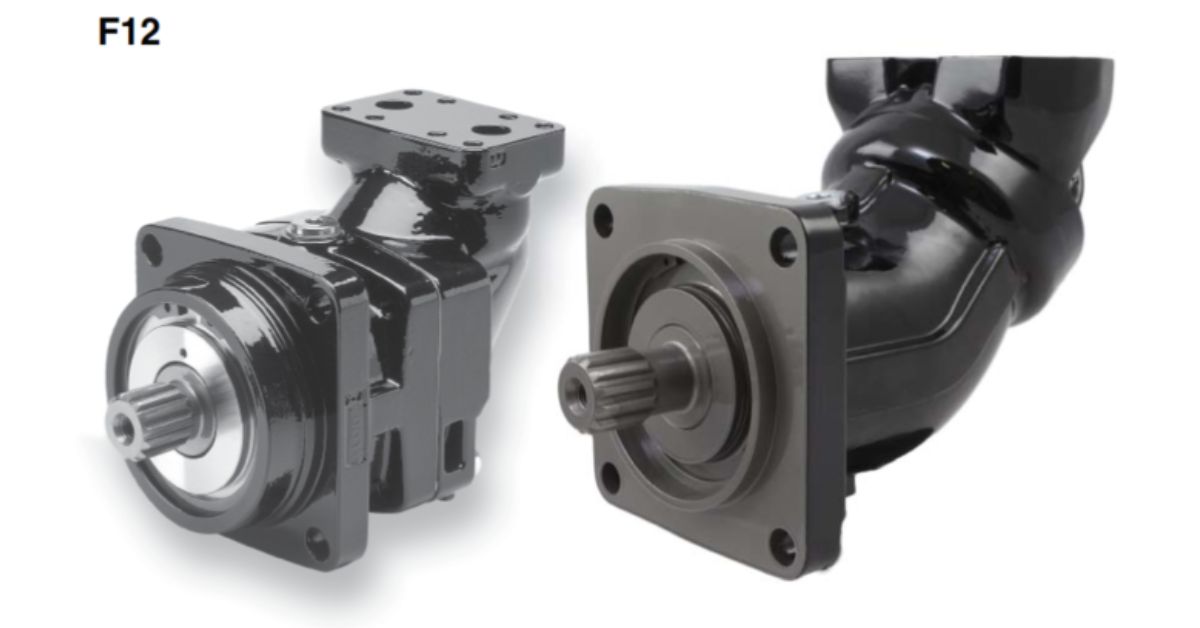

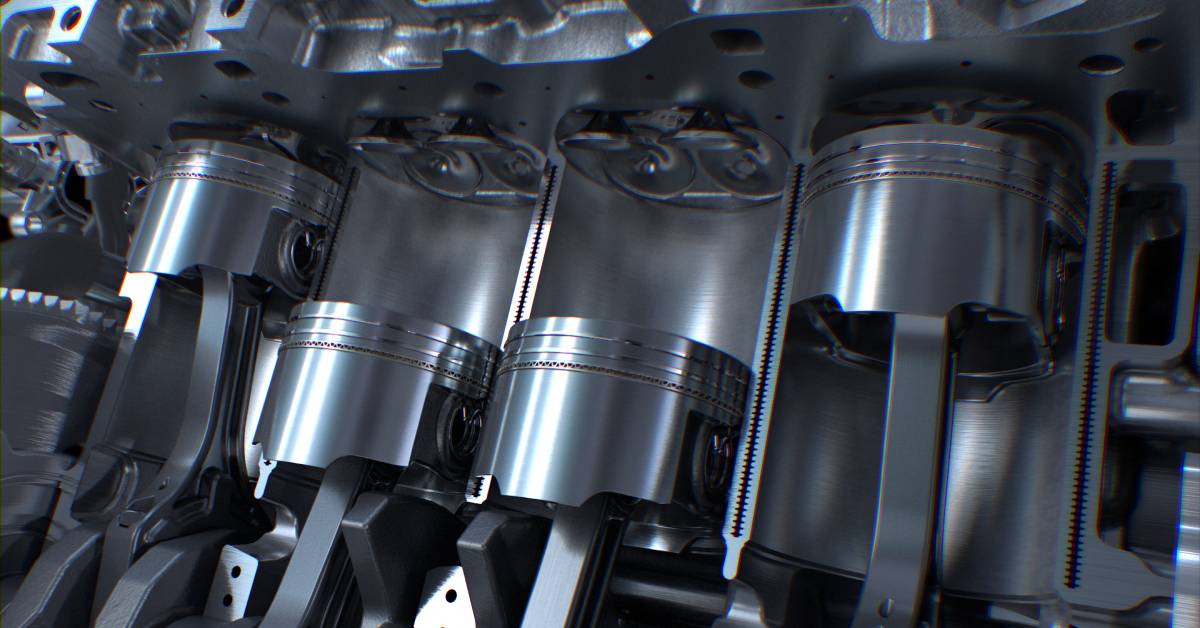

Piston Motors

Piston motors are renowned for their high efficiency and power density, making them suitable for demanding applications. These motors come in two main types—axial piston motors and radial piston motors. Both types utilize pistons arranged within cylinders to convert hydraulic fluid pressure into mechanical motion, but they differ in design and operation.

Key Characteristics

Axial piston motors are known for their compact design and high power output, which makes them ideal for applications with limited installation space. Radial piston motors, on the other hand, offer excellent torque characteristics and are capable of delivering significant power. Both types of piston motors provide precise speed control and can operate at high speeds, making them versatile solutions for various industrial needs.

Industry Applications

Piston motors are commonly used in heavy machinery, such as excavators and cranes, where their ability to deliver substantial power and torque is invaluable. They are also employed in marine applications, powering propulsion systems and winches. In addition, piston motors are used in injection molding and blow molding machines, where their precision and efficiency contribute to producing high-quality plastic products.

Orbital Motors

Orbital motors, also known as gerotor motors, feature a unique design that combines the benefits of gear and vane motors. These motors consist of an internal gear (gerotor) that meshes with an external roller, creating chambers that expand and contract as hydraulic fluid flows through them. This action results in the rotation of the motor's output shaft.

Key Characteristics

Orbital motors are known for their compact size and high torque capabilities. They offer smooth operation and low-speed control, making them suitable for applications that require precise movement. These motors are highly efficient and capable of delivering consistent power across various operating conditions.

Industry Applications

Orbital motors find application in mobile machinery, such as skid steer loaders and mini excavators, where their compact size and high torque characteristics are advantageous. They are used in forestry equipment, powering attachments like saws and mulchers. Additionally, orbital motors are employed in agricultural machinery, including harvesters and sprayers, where their smooth operation and precise control contribute to efficient fieldwork.

Choosing the Right Motor for You

Selecting the appropriate hydraulic motor for your specific application requires careful consideration of various factors. Below are key points to guide you in making the best choice.

Understand Your Power Requirements

Assess the power needs of your application, including the torque and speed requirements. Different hydraulic motors excel under varying conditions, so knowing these specifics will help narrow down your options.

Evaluate Environmental Conditions

Consider the environment in which the motor will operate. Harsh conditions, such as extreme temperatures or exposure to dirt and moisture, may require a more robust motor type, such as gear or piston motors, known for their durability.

Maintenance Considerations

Factor in the ease of maintenance. If downtime is a critical concern, choose motors like gear motors that are simple to maintain and troubleshoot. Vane motors may also be appealing due to their lightweight design and efficiency, but ensure that their maintenance requirements fit within your operational capabilities.

Application Compatibility

Align the motor's characteristics with your specific application needs. For instance, if you require precise torque control for tasks like machine tooling, vane motors may be your best option. Conversely, if high power and efficiency are paramount, piston motors are likely the best fit.

By weighing these considerations against the different types of hydraulic motors discussed, you can make a more informed decision that meets both your performance expectations and operational constraints. This tailored approach will ultimately enhance efficiency and productivity in your industry or application.

Hydraulic motors are integral components in a wide range of industries, offering reliable and efficient solutions for converting hydraulic energy into mechanical motion. Whether you're working on a construction project, agricultural operation, or industrial automation system, understanding the types of hydraulic motors and their applications will empower you to make the best choices for your needs.