The Advantages and Drawbacks of Hydraulic Ball Valves

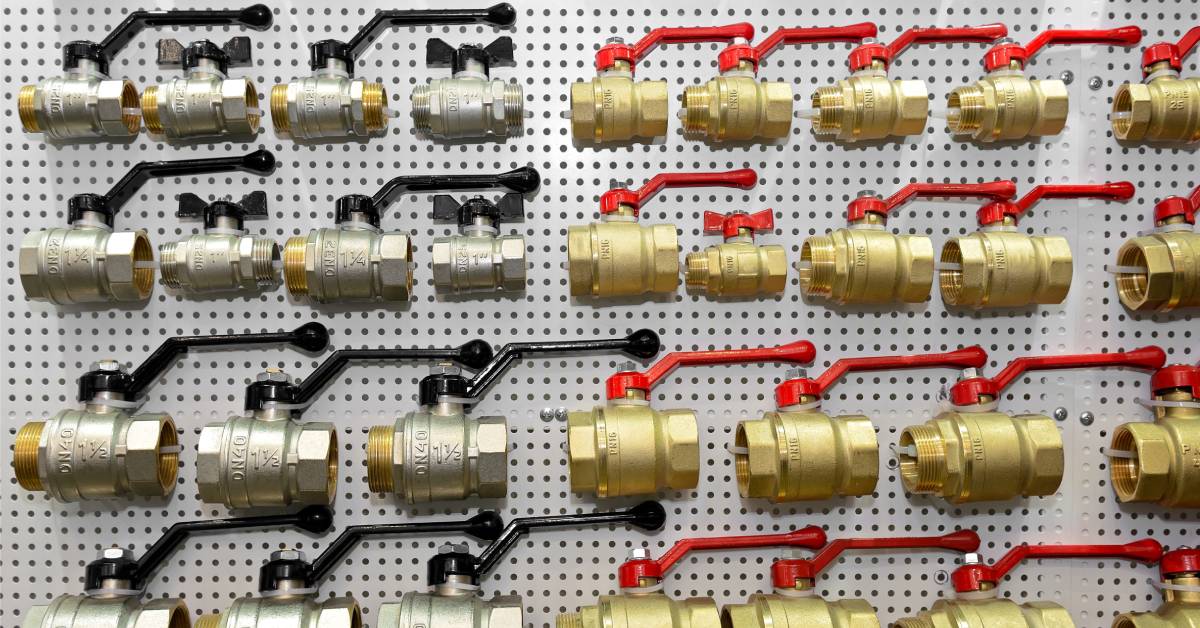

Hydraulic ball valves play a crucial role in the effective management of fluid flow in various industrial applications. As essential components in hydraulic systems, they allow for quick and reliable shut-off, ensuring the safety and efficiency of your machinery and processes. Explore the advantages and drawbacks of this component to gain a balanced view of the functionality and application of hydraulic ball valves. Understanding these benefits and limitations is vital, as they directly affect the performance and longevity of hydraulic systems.

Advantages of Hydraulic Ball Valves

Full Bore Design

One of the primary advantages of hydraulic ball valves is their full-bore design. This feature ensures the hole through the ball matches the pipeline diameter, allowing for unrestricted fluid flow. This is particularly beneficial in applications where maintaining high flow rates is critical.

With no significant pressure drops, the full-bore design enhances system efficiency, making it ideal for high-demand operations. This seamless flow can significantly reduce energy consumption, contributing to overall cost savings in the long run.

Durable Construction

Durability is another significant advantage of hydraulic ball valves. Made from robust materials such as stainless steel, brass, and plastic, these valves are engineered to withstand harsh operating conditions. The solid construction ensures longevity and reliability, even in environments with high pressure and abrasive fluids.

This durability translates to fewer replacements and repairs, reducing downtime and maintenance costs. A well-maintained hydraulic ball valve can perform effectively for years, providing you with a dependable solution for critical applications.

Quick Operation

Hydraulic ball valves are known for their quick operation. The simple design, consisting of a lever or actuator, allows for rapid opening and closing of the valve. This is crucial in emergencies where immediate isolation of fluid flow is necessary to prevent damage or accidents.

The quick response time of hydraulic ball valves makes them suitable for applications requiring frequent switching, such as in automated systems. The ease of operation also means less training for your personnel, enhancing overall operational efficiency.

Tight Sealing

Tight sealing is an important feature of hydraulic ball valves, providing a leak-proof solution that’s essential for maintaining system integrity. The spherical ball fits snugly within the valve seat, ensuring a secure seal when in the closed position.

This tight sealing capability is particularly important in applications involving hazardous or corrosive fluids, where any leakage could pose serious safety risks. The reliability of the seal also minimizes waste and environmental impact, aligning with sustainability goals.

Versatile Application

The versatility of hydraulic ball valves is another key advantage. They are suitable for a wide range of applications, from low-pressure water systems to high-pressure industrial processes. The availability of various sizes, pressure ratings, and material options enhances this adaptability.

Whether they’ll be used in automotive, aerospace, or chemical industries, hydraulic ball valves can be customized to meet specific requirements. This flexibility makes them a go-to choice for if you are seeking adaptable and scalable solutions.

Low Maintenance

Low maintenance requirements are a notable benefit of hydraulic ball valves. The simple design, with fewer moving parts, reduces the likelihood of mechanical failures. Routine inspections and minor adjustments are typically sufficient to keep the valves functioning optimally.

This ease of maintenance translates to lower operational costs and reduced downtime. For maintenance professionals, straightforward upkeep means less time spent on repairs and more time ensuring overall system efficiency.

Drawbacks of Hydraulic Ball Valves

Limited Flow Control

Despite their many advantages, hydraulic ball valves have some limitations. One of the main drawbacks is limited flow control. The binary nature of the valve—either fully open or fully closed—means it is not suitable for applications requiring precise flow regulation.

This limitation can be a drawback in processes where variable flow rates are necessary for optimal performance. For applications requiring finer control, you may need to consider alternative valve types, such as globe valves.

Potential for Wear

The potential for wear is another drawback of hydraulic ball valves. Over time, the constant movement of the ball against the seat can cause wear and tear, leading to valve degradation. This is particularly common in applications involving abrasive fluids or high cycle frequencies.

While durable materials can mitigate this issue, wear and tear are inevitable. Regular inspections and timely replacements are essential to ensure the continued reliability of the valve.

Size and Weight

Size and weight can also be a concern with hydraulic ball valves, especially in large-scale industrial applications. The robust construction necessary for high-pressure environments can result in bulky and heavy valves. This can pose challenges in installation and requires adequate support structures. For systems where space and weight pose constraints, you may need to explore more compact alternatives, like butterfly valves, which offer similar functionality with a smaller footprint.

Initial Cost

Cost is another factor to consider when evaluating hydraulic ball valves. While the initial investment in high-quality valves can be substantial, it's important to weigh this against the long-term benefits. The durability and low maintenance requirements can offset the initial expense over time.

However, for organizations with tight budgets, the upfront cost can be a significant barrier. Exploring cost-effective options without compromising quality is crucial for making informed purchasing decisions.

Dirt Sensitivity

Hydraulic ball valves can be sensitive to dirt and debris, which can affect their sealing and operational efficiency. Dirt and debris particles can accumulate within the valve and cause abrasion or wear, making the use of filters and regular cleaning necessary to maintain optimal performance. In environments where contamination is a concern, implementing effective filtration systems and establish rigorous maintenance protocols to prevent issues is important.

Temperature Limitations

Temperature limitations are another drawback of hydraulic ball valves. While they perform well within a specific temperature range, extreme temperatures can affect their functionality.

High temperatures can cause thermal expansion that leads to potential leaks, while low temperatures can result in material brittleness and reduced flexibility. Understanding the temperature specifications and selecting the appropriate material for the valve is key in ensuring reliable performance under varying temperature conditions.

Understanding the advantages and drawbacks of hydraulic ball valves is essential for making informed decisions in engineering and maintenance. If you're considering integrating hydraulic ball valves into your system, take the time to weigh these pros and cons. When you're ready to optimize your operations, get in touch with our team of experts at Hyspeco today. We can help you choose the right valves for your specific needs and ensure seamless installation.