10 Tips for Maintaining Your Hydraulic Cylinders

From manufacturing to heavy machinery, hydraulic cylinders are the workhorses in many industrial applications. They perform the heavy lifting, literally and figuratively, making operations smooth and efficient. However, maintaining these vital components is crucial to avoid costly downtime and extend their lifespan. Keep reading as we share essential tips for maintaining your hydraulic cylinders that’ll ensure they perform optimally and remain reliable.

1. Keep Your Hydraulic Fluid Clean

One of the fundamental aspects of maintaining hydraulic cylinders is ensuring the hydraulic fluid remains clean. Contaminated fluid can cause significant wear and tear on internal components, leading to premature failure. Regularly check the hydraulic fluid for signs of contamination, such as discoloration, the presence of particles, or a burnt smell.

Replacing or filtering the fluid at regular intervals can prevent costly damage. Remember that employing high-quality hydraulic fluid is crucial. Poor-quality fluid can degrade quickly, reducing the efficiency of the entire hydraulic system. Always refer to the manufacturer's recommendations for the appropriate type of hydraulic fluid for your specific application.

2. Follow a Regular Maintenance Schedule

Implementing a regular maintenance schedule is key to keeping your hydraulic cylinders in optimal condition. Scheduled maintenance allows you to identify and address potential issues before they escalate. Create a comprehensive maintenance plan so that you don’t forget any important steps.

Adhering to a maintenance schedule can prevent unexpected breakdowns and extend the life of the cylinders. Document the maintenance activities you perform on each hydraulic cylinder. This record-keeping helps track the performance and identify patterns that might indicate underlying issues.

3. Perform Regular Inspections and Cleanings

Routine inspection and cleaning are vital for the longevity of hydraulic cylinders and hydraulic pumps. During inspections, look for signs of wear, corrosion, or damage on the cylinder body, rod, seals, and any components of the hydraulic pumps. Cleaning the cylinders and pumps regularly prevents the buildup of dirt and debris, which can compromise their performance.

Use appropriate cleaning agents that don’t harm the cylinder and pump materials. Pay special attention to the rod area and ensure it’s free from contaminants. A clean rod reduces the risk of damaging the seals and other internal components, while clean hydraulic pumps contribute to the overall efficiency and reliability of the hydraulic system.

4. Rotate and Alternate Cylinders

In applications where hydraulic cylinders see extensive use, rotating and alternating the cylinders can distribute the workload evenly. This practice helps prevent excessive wear on a single cylinder and promotes a longer overall lifespan for all cylinders in the system.

Rotate the cylinders at regular intervals based on their usage patterns. Alternating the cylinders ensures that no single component bears the brunt of continuous operation, reducing the risk of failure due to fatigue.

5. Lubricate Hydraulic Cylinder Rods

Proper lubrication of hydraulic cylinder rods is essential for smooth operation and preventing friction-related damage. Apply a suitable lubricant to the rods during routine maintenance to ensure they move freely and don’t wear out prematurely.

Use lubricants that are compatible with the hydraulic fluid and operating conditions. Over-lubrication can attract dirt and contaminants, so apply the right amount to achieve optimal results without causing additional problems.

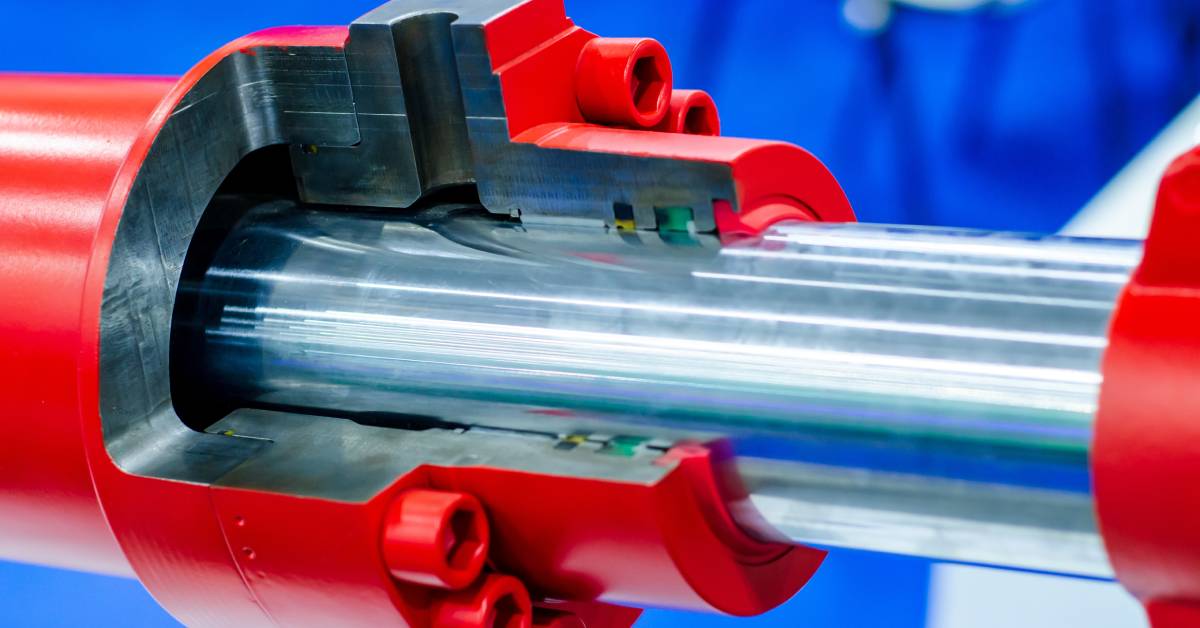

6. Check Seals and Rods

Seals play a critical role in maintaining the integrity of hydraulic cylinders. Regularly check the seals for signs of wear, cracking, or leaks. Replace any damaged seals promptly to prevent fluid leakage and loss of pressure.

Inspect the rods for scratches, dents, or bends. Damaged rods can compromise the sealing surface, leading to leaks and reduced performance. Addressing these issues early can prevent more extensive damage to the cylinder.

7. Monitor for Leaks

Detecting and addressing leaks promptly is crucial for maintaining hydraulic cylinders. Even small leaks can lead to significant fluid loss and reduced system efficiency.

Regularly inspect all connections, fittings, and hoses for signs of leakage. Use leak detection tools if necessary. Ignoring a leak will lead to costly repairs and extended downtime, but finding these leaks and addressing them as quickly as possible can prevent further damage to your system.

8. Avoid Cylinder Side-Loading

Side-loading occurs when an external force is applied to the hydraulic cylinder in a direction other than its intended axis of movement. This condition can cause significant stress on the cylinder and lead to premature failure.

Ensure that you properly align the cylinder with the load you intend it to move. Avoid applying lateral forces that can bend or damage the cylinder. Proper alignment and usage reduce the risk of side-loading and extend the life of the hydraulic cylinders.

9. Control Operating Temperatures

Maintaining optimal operating temperatures is essential for the efficient performance of hydraulic cylinders. Excessive heat can degrade the hydraulic fluid and cause thermal expansion of components, leading to leaks and reduced efficiency.

Monitor the operating temperature of the hydraulic system regularly. Use cooling systems or heat exchangers if necessary to keep the temperature within the recommended range. Controlling the temperature prevents overheating and prolongs the life of both the hydraulic fluid and the cylinders.

10. Maintain System Pressure

Consistent system pressure is crucial for the reliable operation of hydraulic cylinders. Fluctuations in pressure can cause damage to internal components and reduce the system’s overall efficiency.

Regularly check the pressure settings and ensure they’re within the manufacturer's recommended range. You should use pressure relief valves to prevent overpressurization, which can cause catastrophic failure. Maintaining system pressure ensures that the hydraulic cylinders operate smoothly and efficiently.

Bonus Tip: Educate Operators

Educating operators on the proper use and maintenance of hydraulic cylinders is an often overlooked yet vital aspect of ensuring their longevity. Training operators on the best practices in this guide can significantly reduce the risk of damage and downtime. Well-informed operators are more likely to follow maintenance schedules and use the equipment correctly, enhancing the overall efficiency and lifespan of the hydraulic cylinders.

Maintaining hydraulic cylinders is a critical task for ensuring the efficient operation of industrial machinery. By following these tips for maintaining your hydraulic cylinders, you can extend their lifespan, reduce downtime, and improve overall system performance.

If you’re looking for replacement parts for your hydraulic system, browse Hyspeco’s website to find what you need to get your system up and running smoothly. Let us help you optimize your maintenance practices with premium, high-quality products.