What To Consider When Buying Hydraulic Motors

Reliable hydraulic motors are crucial for powering heavy equipment. These motors drive essential machinery operations across various industries. Whether you’re an equipment operator or a mechanical engineer, understanding what to consider when buying hydraulic motors is key for optimizing performance and ensuring longevity. Discover what vital considerations you should keep in mind to guarantee your machines run smoothly.

Types of Motors

Choosing the right type of hydraulic motor is crucial for the efficiency and reliability of your machinery. Different motors offer different benefits and qualities, such as speed, torque, and size, depending on the application. Understanding these differences helps you select a motor that meets the specific requirements of your equipment while optimizing its performance and extending its operational life.

Vane Motors

These motors offer good speed control and can deliver moderate levels of torque. Vane motors operate using a rotor with multiple extending vanes, which adapt to the housing walls.

Gear Motors

Known for their simplicity and durability, gear motors are cost-effective and suitable for moderate-speed, high-torque applications. They usually consist of two gears—an input gear and an output gear—that mesh together to create movement.

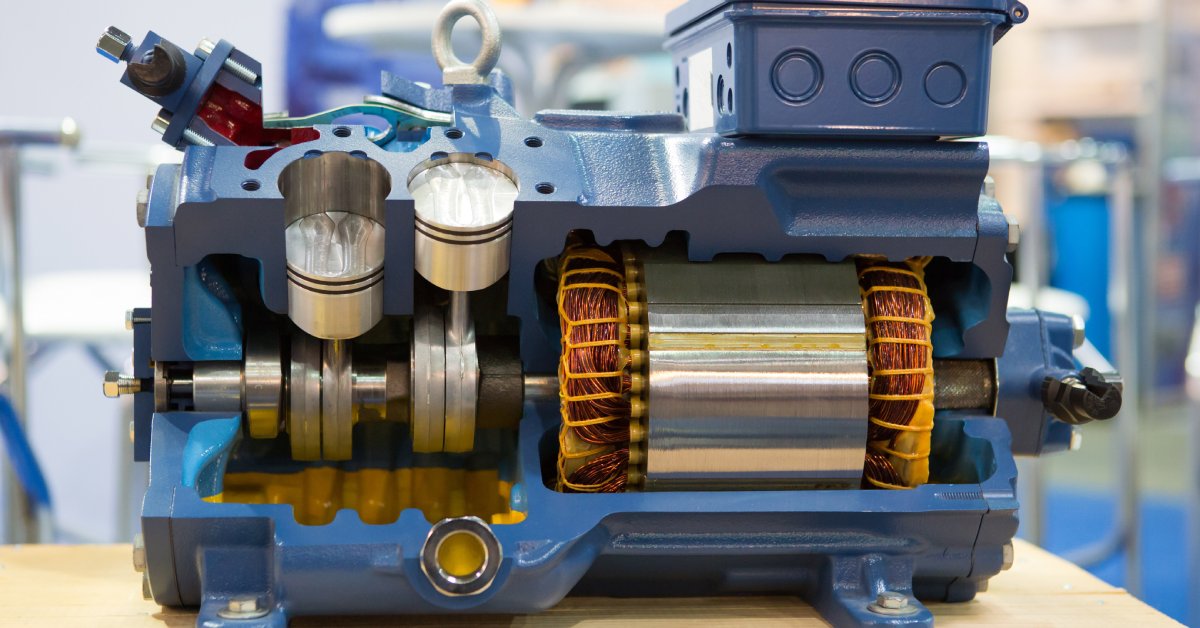

Piston Motors

Ideal for high-pressure tasks, piston motors provide superior efficiency and precision. They use a series of pistons in a cylinder block to convert hydraulic energy into mechanical energy. Because of their power, they’re often involved in demanding industrial applications.

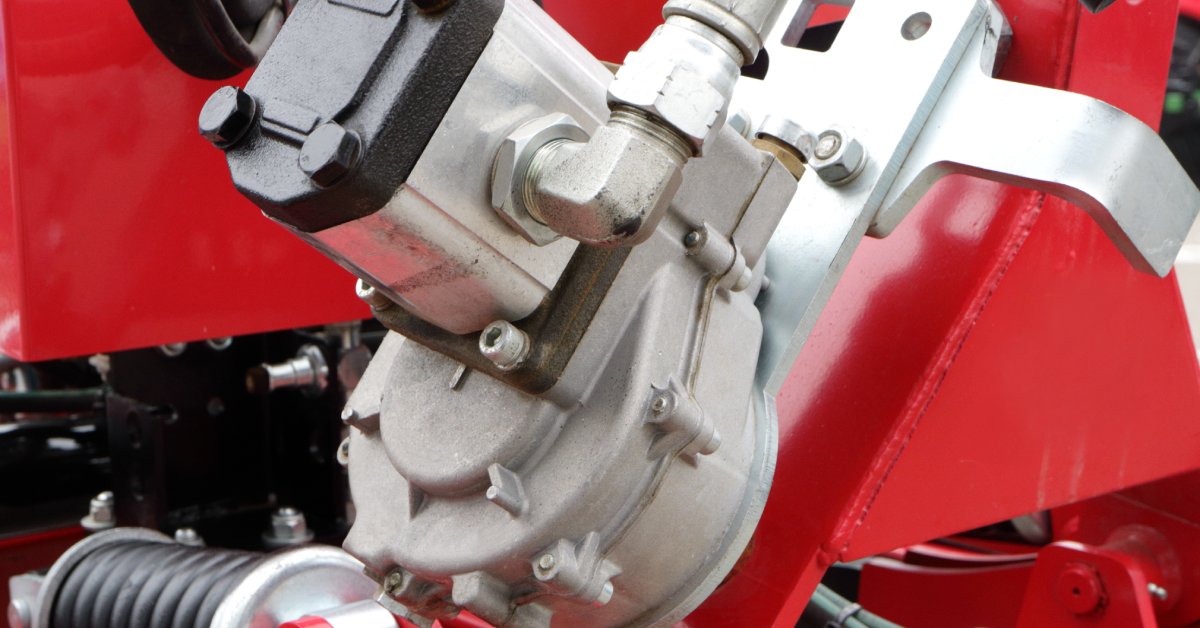

Application Needs

.jpg)

Determining your specific application needs is a fundamental step in selecting the appropriate hydraulic motor. Different applications require varying levels of power, speed, and torque.

For instance, construction machinery might need robust motors capable of handling high loads, while agricultural equipment might prioritize efficiency and reliability above all else. Consider the operational environment you have in mind and the tasks the motor will need to perform. Aligning the motor with these requirements will help it meet your performance expectations in its intended application.

Power Requirements

Power requirements should also play a role in the selection process of a hydraulic motor. Evaluating the horsepower and torque necessary for your specific application is crucial to avoid underperformance or over-specification. Certify that the motor you select can deliver sufficient power consistently under various load conditions.

It’s advisable to consult with a technical expert or refer to machinery specifications to accurately gauge the power requirements. By aligning the motor’s power capabilities with your needs, you guarantee operational efficiency and longevity.

Energy Efficiency

Energy efficiency is more important than ever. Selecting a hydraulic motor that operates efficiently can lead to significant savings in energy costs and reduce the carbon footprint of your operations. Consider motors that come with energy-saving features or certifications, as these often translate to a more sustainable performance.

While energy-efficient motors might have a higher initial cost, they typically pay off in the long run through reduced energy consumption and lowered operational expenses. Prioritizing energy efficiency isn’t just great for the environment; it’s also great for your bottom line.

Size and Compatibility

Size and compatibility are critical considerations when integrating a new hydraulic motor into your existing machinery. The motor must fit seamlessly within the designated space and work in harmony with other components.

Carefully measure the available space and verify that the motor’s dimensions align with your equipment’s requirements. Additionally, ensure compatibility with existing hydraulic systems, such as pumps and controls. Overlooking size and compatibility can lead to costly modifications or operational inefficiencies, so it’s essential to address these aspects early in the selection process.

Operating Environment

The operating environment greatly impacts the performance and durability of a hydraulic motor. Specifically, humidity, dust, temperature, and exposure to corrosive substances will affect the motor’s performance, so take these elements into account.

For instance, motors operating in harsh environments may require additional protection or specialized materials to withstand adverse conditions. Choose a motor designed to handle the specific environmental challenges it will face. Doing so minimizes wear and tear on the part, reduces maintenance costs, and extends the motor’s lifespan.

Maintenance Requirements

Understanding the maintenance requirements of a hydraulic motor is vital for ensuring optimal performance and minimizing downtime. Some motors require frequent maintenance, including oil changes and component inspections, while others are designed for lower-maintenance operation. However, all motors require some degree of care to operate at their best.

Evaluate the availability of maintenance resources, including trained personnel and replacement parts, when selecting a motor. Keeping up with maintenance needs allows you to implement a proactive maintenance schedule, thus prolonging the motor’s operational life and reducing unexpected failures.

Availability of Spare Parts

It’s easy to overlook having access to spare parts, but this access is essential for supporting the maintenance and repair of hydraulic motors. When spare parts are scarce or challenging to procure, it can lead to prolonged downtime and increased costs if your motor fails.

Choose a motor for which spare parts are readily available, either from the manufacturer or authorized distributors. Doing so facilitates quick repairs or replacements, minimizing downtime and disruption to operations. Prioritizing motors with accessible spare parts is part of a smart long-term strategy.

Brand Reputation and Customer Reviews

Brand reputation and customer reviews can offer valuable insights into the reliability and performance of the hydraulic motors you’re considering. Established brands, such as Parker Hannifin, have track records of quality and innovation, which can provide you with peace of mind. However, you should still perform your due diligence and read reviews for each specific motor you are considering for your operations.

Exploring customer reviews and testimonials can reveal real-world experiences and potential issues. Positive reviews and a strong brand reputation are indicators of a trustworthy product that delivers on its promises.

Balancing Cost With Quality and Performance

Cost is always a factor in purchasing decisions, but make sure you balance cost with quality and performance when selecting a hydraulic motor. While it might be tempting to go with a cheaper option, compromising on quality can lead to higher costs in the long run due to frequent repairs or replacements.

Evaluate the total cost of ownership, which includes purchase price, operational costs, and maintenance expenses. Investing in a high-quality motor ensures reliable performance, reduces downtime, and ultimately provides better value for money.

Knowing what to consider when buying hydraulic motors will enhance the efficiency, performance, and reliability of your machinery. Each aspect you must consider plays a valuable role in matching the right motor to your existing equipment.

At Hyspeco, we are a proud Parker Hannifin distributor for a variety of products, including high-quality Parker hydraulic motors. Should you have any questions or need expert guidance in finding the perfect motor for your application, reach out to our knowledgeable team. We are here to help you optimize your equipment.