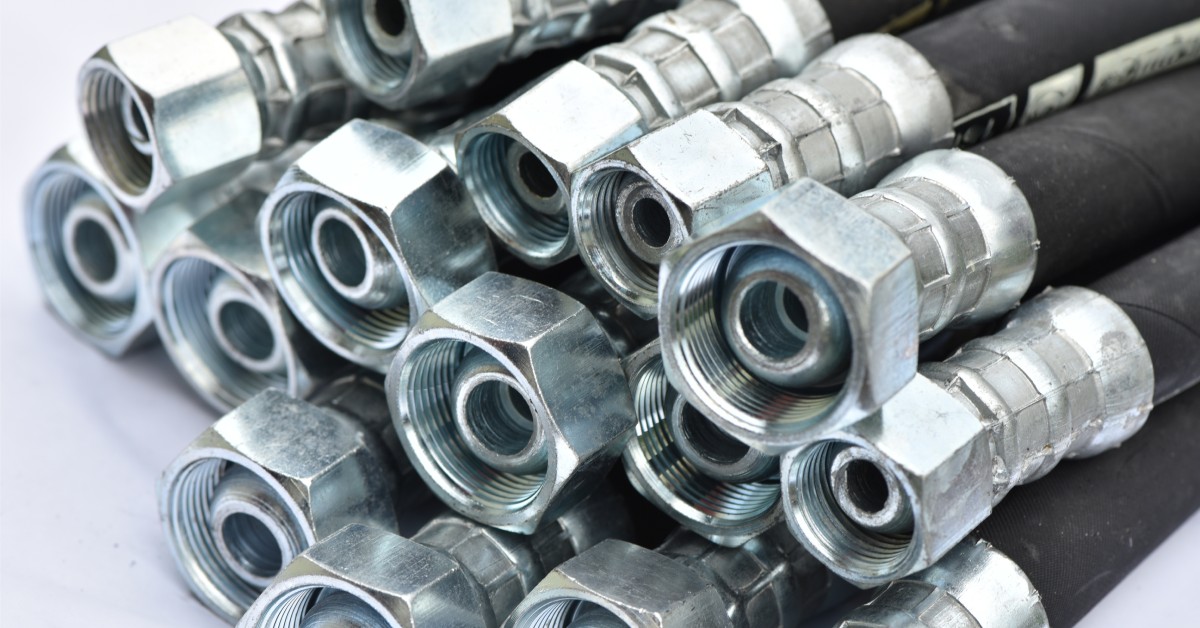

How To Identify Different Types of Hydraulic Hose Fittings

Imagine the frustration of a hydraulic system failure because of a mismatched fitting. Using one wrong simple component will affect the whole system and cause issues and costly downtime. Being able to identify different types of hydraulic hose fittings and understanding what is available to you can help avoid system failure and keep your machinery running smoothly. After reading this guide, you’ll be able to choose the right fittings for your specific needs, avoiding costly mistakes and boosting system performance.

Why Are There Different Hydraulic Hose Fittings?

The diversity in hydraulic hose fittings exists to accommodate the wide variety of applications, pressures, and environments in which hydraulic systems operate. Different fittings are designed to meet specific requirements, such as varying pressure ratings, fluid compatibility, and connection standards. This versatility ensures that the hydraulic system can maintain integrity and performance regardless of the complexities or demands of its use, ultimately enhancing reliability and safety.

Common Types of Hydraulic Hose Fittings

Understanding the various types of hydraulic hose fittings is crucial for selecting the right component for any given application. Below are some of the most common types and their unique characteristics:

O-Ring Face Seal

O-ring face seal (ORFS) fittings provide a secure, leak-proof connection. They feature an O-ring seated in a groove on the face of the fitting, which mates with a flat-face counterpart. This design is especially effective in high-pressure applications, minimizing the risk of leaks caused by vibrations or mechanical shocks.

Flange Fittings

Flange fittings are ideal for connecting large-diameter hoses and piping. These fittings consist of a flange head that mates with a corresponding flange on another component, which is secured by bolts and often involves a seal or gasket. Flange fittings are sturdy and easily assembled, making them suitable for heavy-duty, high-pressure environments.

Mated Angle

Mated angle fittings match two components with angled sealing surfaces, commonly using tapers such as 37° (JIC) or 45°. This type of fitting provides a metal-to-metal seal that can withstand high-pressure conditions and is often used in rigid, vibration-prone installations. The angles ensure tightness and reliability even under fluctuating pressures.

Quick Connect Fittings

The design of quick connect fittings is utilized for rapid connection and disconnection without the need for tools. They typically feature a push-and-pull mechanism, using a ball or poppet valve to automatically seal when disconnected. Quick Connects are highly efficient for applications needing frequent maintenance or where you need to minimize downtime.

Tapered Threads

Tapered Thread fittings rely on thread deformation to create a seal. Common types include NPT (national pipe taper) and BSPT (British standard pipe taper). These fittings are widely used for their simplicity but are generally recommended for lower-pressure applications as they can be more susceptible to leaks under high pressures compared to other types.

By understanding these common types of hydraulic hose fittings, you can make informed decisions that enhance the efficiency, reliability, and safety of your hydraulic system.

Materials Used in Hydraulic Hose Fittings

Stainless Steel

Stainless steel fittings are excellent for corrosion resistance, making them ideal for use in harsh environments or with corrosive fluids. These fittings offer high strength and durability to provide your systems with long-term reliability, even under extreme conditions.

Brass

Brass fittings are commonly used due to their good corrosion resistance and machinability. They are particularly suited for low to medium-pressure applications and offer a balance of strength and pliability, making them easier to install and seal.

Plastic

Plastic fittings, often made from materials like nylon or thermoplastic, are lightweight and resistant to corrosion. This type of fitting is suitable for low-pressure applications and provides an economical choice for systems where metal fittings are unnecessary.

Carbon Steel

Carbon steel fittings are known for their strength and durability, making them suitable for high-pressure applications. They are less resistant to corrosion compared to stainless steel but offer excellent mechanical properties and are often used when cost and strength are primary concerns.

Applications of Different Hydraulic Hose Fittings

- Agriculture: Connecting hydraulic systems in tractors, harvesters, and irrigation equipment

- Construction: Used in heavy machinery like excavators, bulldozers, and cranes for efficient hydraulic operation

- Automotive: Employed in hydraulic brakes, power steering, and suspension systems for reliable performance

- Aerospace: Critical for hydraulic systems in aircraft where durability and high-pressure resistance are essential

- Manufacturing: Integral to assembly lines and robotic systems requiring precise fluid control

- Oil and gas: Utilized in drilling rigs and refineries where high-pressure and corrosion-resistant fittings are necessary

- Mining: Used in equipment such as hydraulic shovels and drills, operating under high-pressure and harsh conditions

Hydraulic hose fittings play a vital role in various applications, each requiring specific characteristics to maintain optimal performance. From construction to manufacturing, the selection of fittings can significantly impact system efficiency and reliability.

How To Identify the Right Fitting for Your System

Selecting the right hydraulic hose fitting for your system involves several crucial factors that ensure compatibility and optimal performance. Here’s a guide to help you identify the right fitting:

Compatibility With the System

Before anything else, you need to confirm that the fitting type is compatible with your existing system. This includes verifying that the fitting matches the hose or piping connections, as well as the type of fluid being transported. Compatibility with connection standards such as JIC (Joint Industry Council), BSP (British Standard Pipe), or NPT (National Pipe Tapered) also needs to be verified.

Pressure Rating

One of the most critical aspects of choosing a hydraulic hose fitting is its pressure rating. Your chosen fitting must be able to withstand the maximum pressure the system will be subjected to without the risk of failure. Checking the pressure rating for Parker hydraulic hoses and their fittings ensures that they are capable of working together under normal operating conditions and any potential pressure surges.

Temperature Range

Temperature plays a significant role in the integrity of hydraulic systems. Make sure the fittings you choose can handle the temperature range of your application. This includes both the ambient temperature of the working environment and the temperature of the fluid being transported. Overheating can cause fittings to degrade, while extreme cold can lead to brittleness.

Environmental Conditions

Finally, you must consider the environmental conditions of the hydraulic system. Factors such as exposure to chemicals, corrosion, moisture, and abrasive environments can affect the longevity and performance of the fittings. For instance, stainless steel is excellent for corrosive environments, while brass might be suitable for less harsh conditions. Ensuring that the material of the fitting can withstand these conditions will enhance the system's reliability.

By thoroughly evaluating these factors, you can make an informed decision in selecting the most appropriate hydraulic hose fitting that will provide your systems with efficiency, reliability, and safety.

Downtime can be costly. Avoid this expense by knowing how to identify different types of hydraulic hose fittings so you can choose a compatible component for your system. Guarantee the success of your equipment by choosing the right hydraulic hose fitting.

If you’re looking for hydraulic hoses and fittings, consider Hyspeco. We have the high-quality hydraulic parts you need for an optimal system setup. Browse our wide variety of parts today to find what you need.