.png)

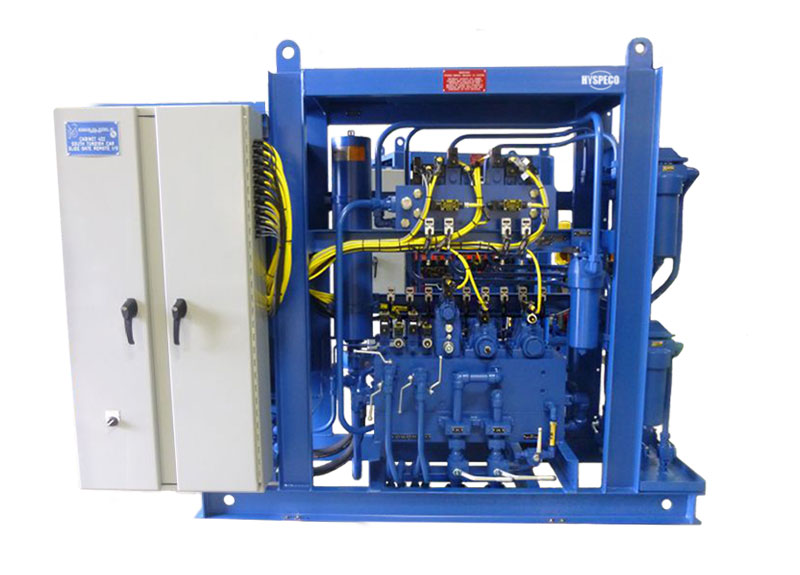

Custom Fabrication and Machine Building

We offer a wide variety of fabrication and industrial production services. Focused mainly within the Hydraulic, Pneumatic, and Electrical realm, our fabrication team works diligently to manufacture every needed specification to absolute perfection.

We offer a wide variety of fabrication and industrial production services. Focused mainly within the Hydraulic, Pneumatic, and Electrical realm, our fabrication team works diligently to manufacture every needed specification to absolute perfection.

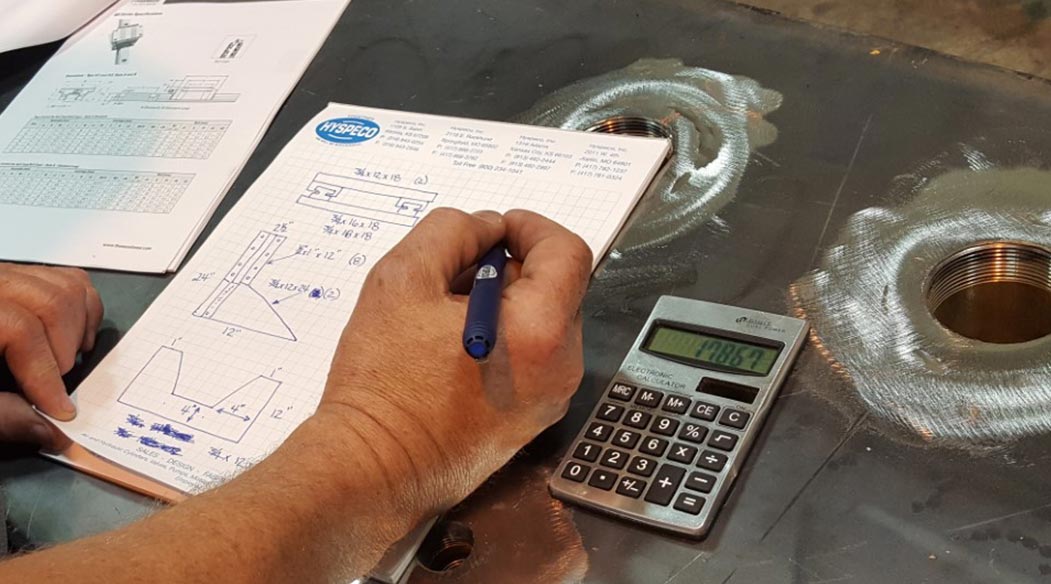

After a Hyspeco engineering consult, the specifications and needs of your Power Unit are communicated to our fabrication team. From then on our engineering and fabrication team consistently interact during the design, fabrication and build process, constantly updating you on the progress of your custom made machinery. Build combinations:

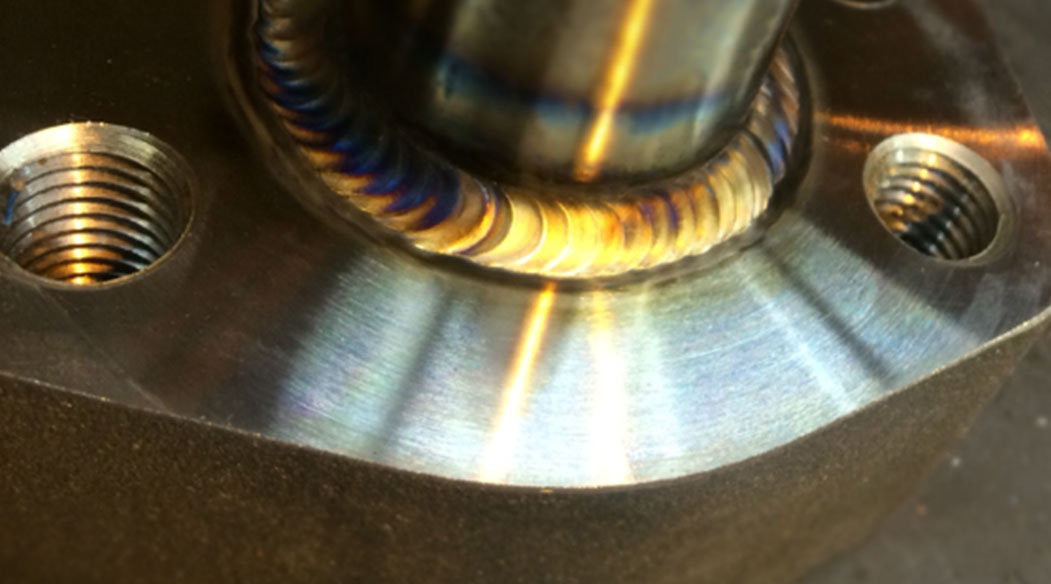

- Hydraulic/Pneumatic Manifold Assemblies

- 150-200 HP HPU Testing

- Non-weld Tube Assemblies

- Hydraulic Cylinders

- Control Systems Integration

- System Data Logging

Please note that our fabrication abilities are not limited to those listed above.

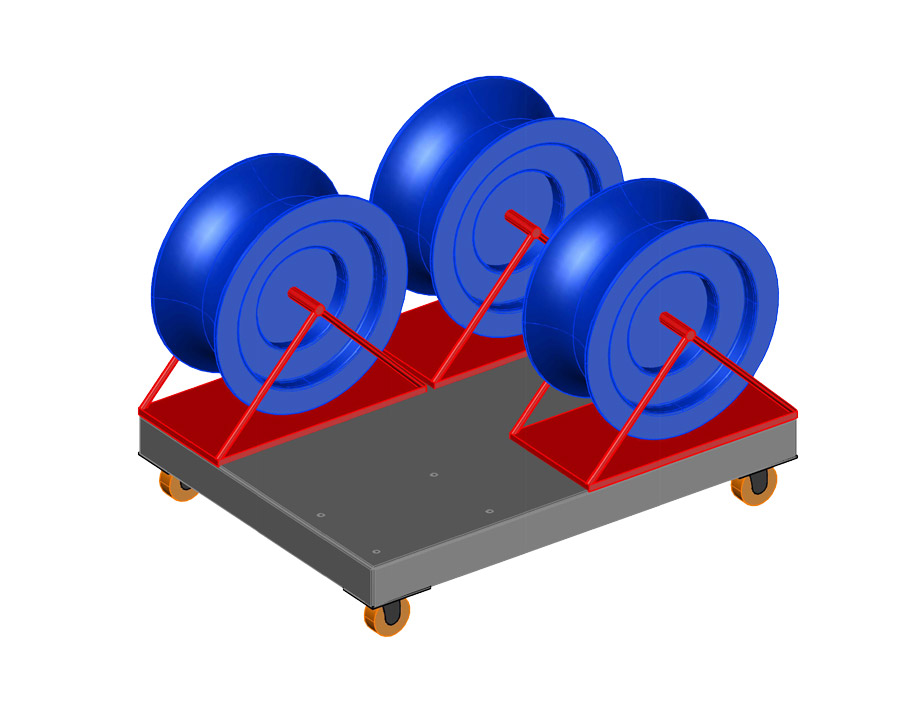

Hyspeco can assist with custom industrial carts, and ground support test mules. Examples of equipment characteristics are as follows:

- Specified Horse Power

- Specified GPM (Gallons Per Minute)

- Specified PSI

- Placement Design of Unit Fixtures

Technology integration examples:

- D03 Valve Testing

- Hydraulic Motor

- Beckhoff Controls

- Data Logging

- Parker Technology

- Pneumatic Capabilities

An Industrial Cart design provides mobile power regulation opportunities that a static unit cannot. Outfitted with industrial grade casters and support frame, the design combinations are limitless.

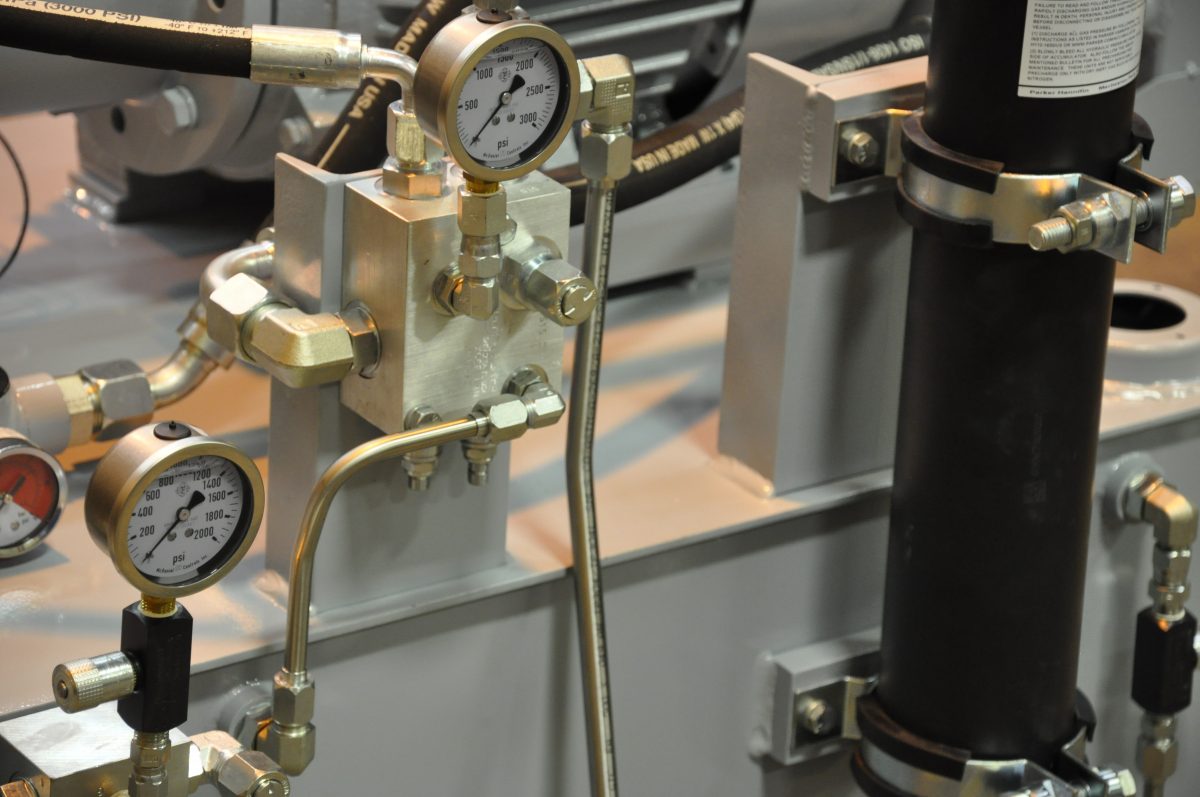

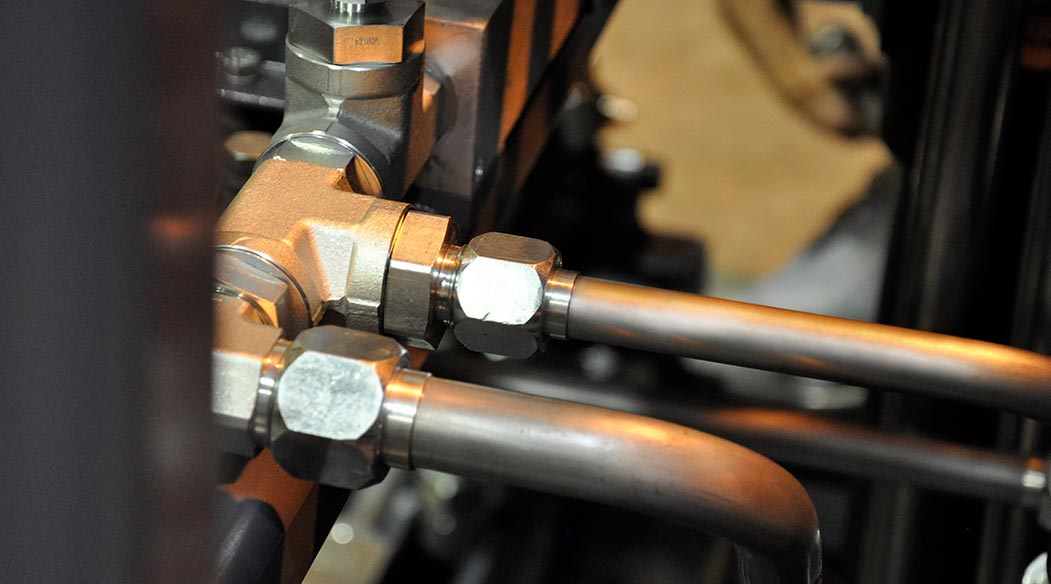

Specialized hard welded tubing at your fingertips. Stainless & Carbon Steel material types, weld or seamless, and multiple end fitting options that include Seal Lock, JIC, Inverted Flare and more. Bending options vary.

O.D. sizing options:

- 3/16?

- 1/4?

- 3/8?

- 1/2?

- 5/8?

- 3/4?

- 1?

- 1 1/4?

- 1 1/2?

Special tubing O.D., material, and bends available upon request. Please contact us for more details.

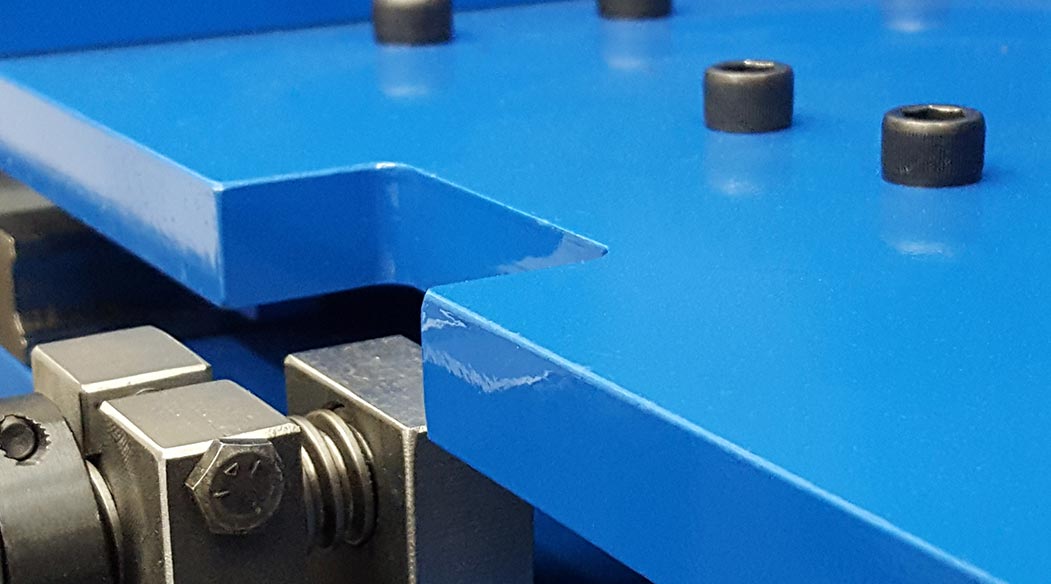

Metal Fabrication

Hyspeco has or will source the abilities to cut, bend, weld, and assemble various metals in order to achieve the creation of custom machinery. With experienced technicians on hand and multiple in-house resources, our metal building capabilities are 2nd to none and our structural design potential is limitless.

Our engineers design with quality and cost efficiency in mind and our fabrication team builds to absolute specifications, providing the finest finished product in the industry.

Preventative maintenance

Our service contracts offer follow-up maintenance and machine monitoring on the product that we build. Machine maintenance is key in any scenario, and we want to make sure that your new machinery continues to operate properly and without fail in the years to come.

We not only offer service and maintenance on Hyspeco-built equipment, but also on hydraulic equipment you may already own. Learn more about our Preventative Maintenance Program.

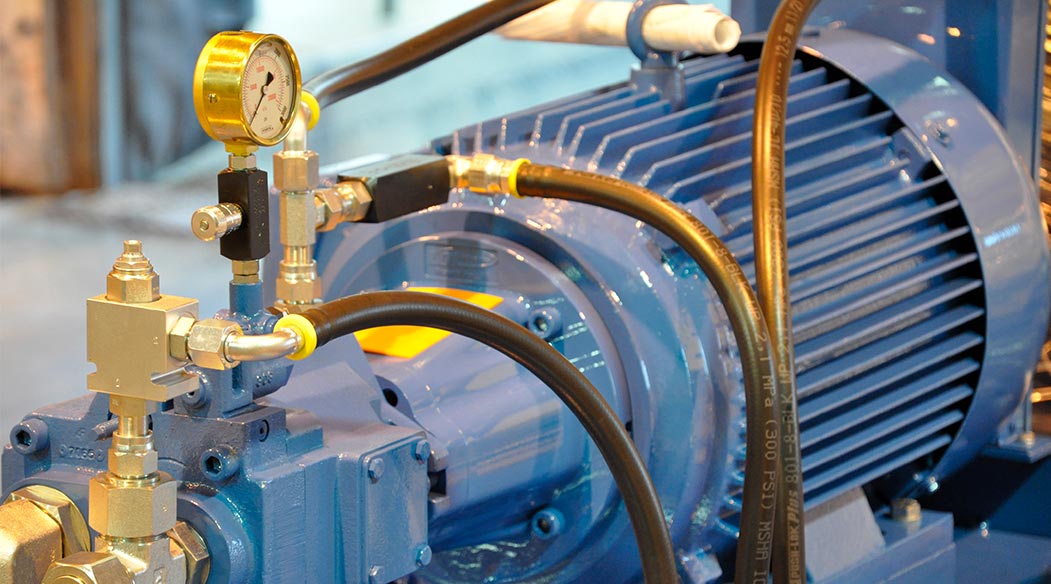

Performance testing

Each piece of machinery that we produce is rigorously tested to meet specific qualifications. Our quality test program ensures that our machines arrive ready to perform. We consistently strive to meet our ISO 9001:2015 Certification requirements.

Analytical Integration

Innovation is what drives us to be the absolute best. When you choose us to build your machinery, you are given modern technological options that aid in monitoring, troubleshooting, autonomous control, system data logging and more.

The Parker SensoNode is a perfect example of the ground breaking technology that helps to maximize the health of your machinery.