Parker HS2TFI1.00-NC48.000 4 ft L PTFE Tubing

Product Info

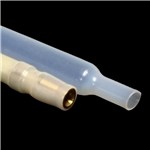

When the heat is on, Parker manufactures PTFE Heat Shrink Tubing, a fluoropolymer heat shrink that protects components from heat, sparks and contaminants while handling long term exposure to temperatures as high as 500°F (260°C). When heated, the heat shrink conforms to the size and shape of the original object, providing a protective covering. PTFE AWG 2:1 and Fractional 2:1 heat shrink are produced in Heavy Wall, Standard Wall, Thin Wall and Light Wall designs and supplied in an expanded state, allowing easy slippage over cables, fittings and other protrusions. AWG heat shrinkable tubing is typically used when repairing electrical wiring, fittings, cords and other small objects that need to be protected from heat, water, dust or corrosion. Most standard products are supplied with a thin wall, promoting quick installations. The thin wall also keeps the tubing flexible when flexibility is an issue. Fractional 2:1 heat shrink is used to protect larger objects like electrical harnesses, instruments, or even lighting where a breakage would compromise the operation. The Parflex division also offers turnkey services for Fluoropolymer Heat Shrink. Even on very difficult applications, such as copper coils, Parker can apply the heat shrinkable tubing onto your product to eliminate kinks and wrinkles and ensure consistency. In addition, outsourcing reduces scrap and allows you to use the product immediately upon receipt without using additional space in your warehouse for carrying inventory.

Features:

Applications:

Technical Specifications:

Markets:

Electronics | Government | IndustrialItem Specifications

-

Natural

-

4 ft

-

PTFE

-

500 °F 260 °C

-

Wiring, Chemicals

-

1.33 Inch 33.8 MM

-

-100 °F -75 °C

-

Tubing

-

Fluid Connector

-

1.02 Inch 25.9 MM

-

0.05 Inch 1.27 MM

-

Heat Shrink

-

Fractional 2:1, Heavy Wall